Precast concrete box culverts are manufactured in a series of steps to ensure they meet specific design and structural requirements. These culverts are typically used to convey water, usually under roadways or railways, and can vary in size and shape depending on the project's needs. Here is an overview of the design, manufacturing and installation process for precast concrete box culverts:

1. Design and Planning

The design phase involves determining the dimensions, load-bearing requirements, and other applicable specifications for the box culvert.

2. Engineering

Engineers undertake the structural design of the units in compliance with the design specifications and create detailed plans and drawings to guide the manufacturing process.

3. Quality Planning

Quality documentation is prepared, including an Inspection & Test Plan (ITP).

4. Material Selection

High-quality materials are selected for the construction of the culvert in compliance with the design specifications, including concrete, reinforcing steel, formwork materials and cast-in items.

5. Mould or Formwork Construction:

Steel moulds are either built or modified to suit the shape and dimensions of the box culvert. Timber formwork may also be utilised for some units e.g. custom shape wing walls.

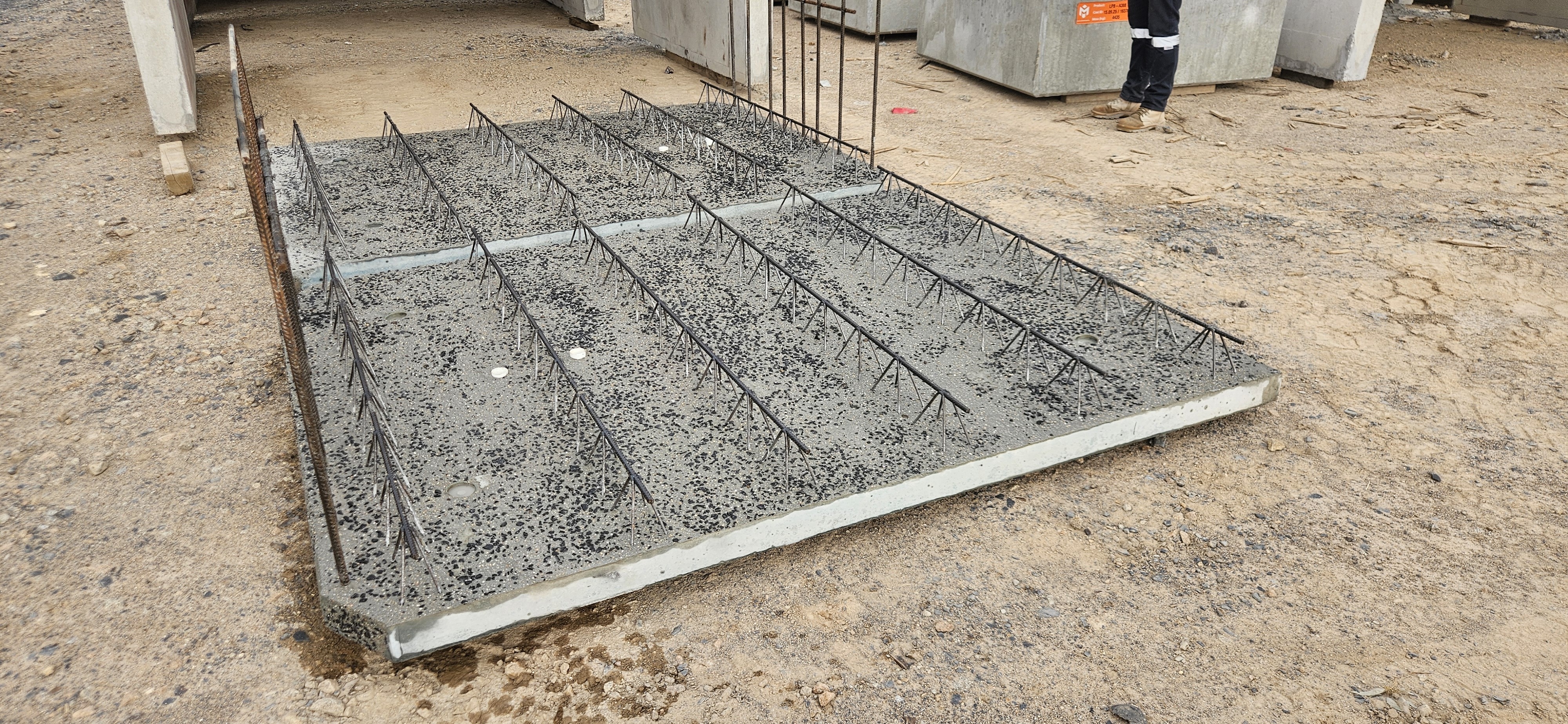

6. Reinforcement Installation:

Steel reinforcement bars are welded into cages and placed into the moulds. The rebar provides added strength and structural integrity to the culvert.

7. Concrete Mixing and Pouring:

Concrete is batched according to the project's specifications, including the desired strength and durability. The concrete is poured into the formwork, consolidated with vibration, and finished.

8. Curing:

After casting, the concrete is cured for a specific period of time depending on the process used. Common methods include steam curing, membrane curing or wet curing. Proper curing is essential to ensure the concrete achieves its intended strength and durability.

9. Quality Control:

Quality control measures and checks are implemented throughout the manufacturing process to ensure the box culvert meets design specifications. This includes testing of concrete samples for strength and consistency.

10. Demolding:

Once the concrete has cured sufficiently, the moulds are opened and precast elements are removed. Care is taken to prevent damage to the newly formed structure during this step.

11. Finishing

The culvert may undergo finishing processes to smooth surfaces and ensure the box culvert meets aesthetic and functional requirements.

12. Transportation and Installation

Precast concrete box culverts are transported to the construction site and positioned in the excavated trench. They are installed according to the project design, ensuring proper alignment and joint sealing.

13. Backfilling and Site Restoration

Once the box culvert is in place, the surrounding area is backfilled with soil or other suitable material as specified. The site is then restored to its original condition, including road or railway surface restoration if applicable.

The manufacturing process for precast concrete box culverts involves precise planning, skilled labour, and quality control measures to produce durable and structurally sound components for infrastructure projects. These culverts are favoured for their speed of installation, longevity, and reliability in managing water flow beneath roads and railways.