Learn About Our Extensive Capabilities.

Modcast has established strong partnerships with a team of highly skilled structural, civil, and geotechnical engineers. They specialize in providing meticulously designed and optimized precast elements for your project.

Our esteemed design panel consists of engineers who are prequalified according to the strict Vicroads / DTP requirements for large culverts.

To ensure the utmost effectiveness of precast in your project, we encourage you to engage with our team at the earliest stages of the design process.

Our skilled and experienced in-house team specializes in designing, constructing, and modifying high-quality steel moulds tailored to your specific culvert project requirements.

With our in-house capabilities, we are able to deliver custom products promptly and efficiently scale moulds for even the largest projects.

Equipped with cutting-edge CNC equipment in our spacious custom-built workshop, our mould fabrication team ensures the highest level of precision and quality.

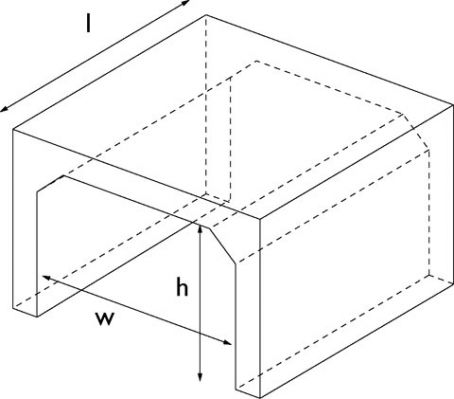

With a wide inventory of more than 50 box culvert moulds, Modcast is fully equipped to handle a diverse range of culvert projects and scopes.

Our extensive range of moulds covers all Australian Standard sizes, spanning from 300 to 4200mm. Additionally, many of our moulds feature a unique modular system, allowing for quick and seamless transitions between different sizes and customized applications.

Rest assured, our in-house manufactured moulds are meticulously built to meet the highest standards, ensuring efficient production and dependable castings that endure the test of time.

Our expansive facility in North Wangaratta, Victoria, showcases a vast 16,000 square metre lay down and storage area.

This highly secure fenced section offers ample storage space for even the most sizable projects during curing, minor rectification, and delivery staging.

Feel free to consult our team regarding how we can efficiently store your finished components and strategically plan deliveries to seamlessly align with your installation program.

Our production process incorporates a state-of-the-art steam curing system with computerized controls for precise temperature regulation and monitoring.

Steam curing ensures the most effective curing process, resulting in improved durability.

Additionally, steam curing facilitates rapid early strength development, enabling next-day stripping and fast casting cycles to expedite your project.

The Modcast production team utilizes a diverse selection of lifting equipment to safely and efficiently strip, handle, and load elements weighing up to 12,000 kg.

For larger elements, we collaborate with external crane contractors to handle the lifting and loading process.

The skilled team at Modcast uses top-of-the-line equipment and precision engineering to create high-quality, high-volume cages for our casting department.

We source processed bar from a variety of trusted suppliers and expertly fabricate it into cages in our spacious fabrication bay. Additionally, we have the capability to cut and bend bar in-house to meet any urgent requirements.

The Modcast logistics team partners with a range of haulage contractors to safely deliver your culverts to site.

Modcast is a premium supplier of Precast Concrete Products.

With a focus on effective lead times and custom products, you can have the Modcast experience today!

Copyright 2023 Modcast Pty Ltd. All rights reserved. >>Privacy Policy