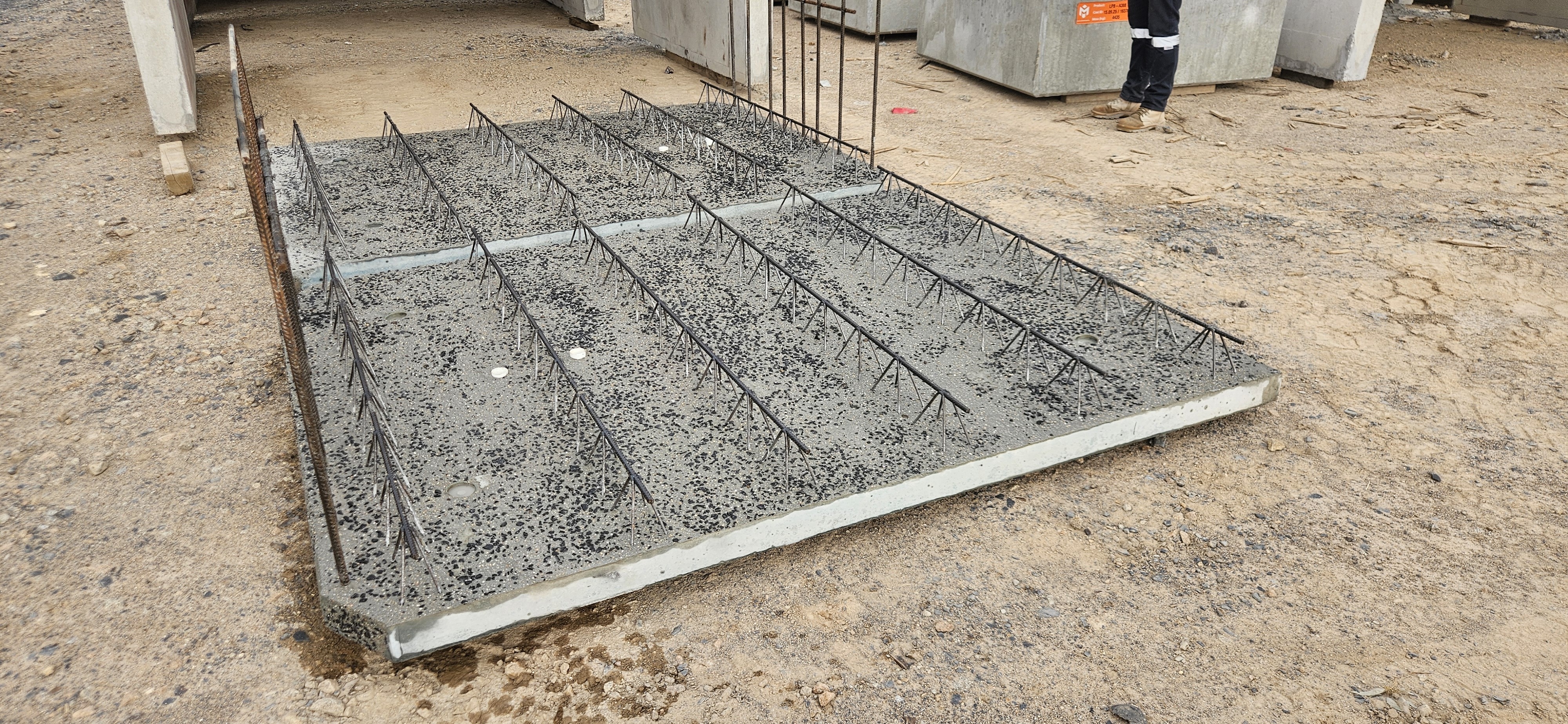

Precast bases and lids are commonly utilized in small, single-cell culvert structures; however, it is important to explore their advantages for larger, multicell structures. In specific scenarios, large precast bases can offer substantial benefits to your project, such as:

Time Constraints

Precast bases are ideally suited for projects that require completion within a very constrained timeline, such as during weekend railway possessions and road closures in off-peak periods. By removing the necessity for forming, steel fixing, pouring, and curing an in-situ base, contractors can potentially reduce the project timeline by up to a week.

For projects with less stringent schedules, precast bases can offer additional flexibility and contingency for other project components.

Access Limitations

Precast bases are particularly advantageous in scenarios where access is restricted, such as in a deep excavation. In these cases, the bases can be efficiently installed using cranes, thereby minimizing the need for extensive labor in confined spaces.

Remote Locations

In projects situated in remote areas, utilizing precast bases can significantly lower the expenses associated with transporting specialized tradespeople and premix concrete over long distances. This approach allows installation contractors to efficiently complete the installation process with fewer site visits and reduced travel requirements.

Reduced Trades

In high-risk sites and locations, the use of precast bases can effectively decrease the number of personnel and specialized trades needed on-site. This reduction can lead to significant savings in induction and supervision expenses for the contractor.

Other Considerations

When evaluating the benefits of precast bases, it is crucial to also consider the following factors:

Weights - Large multicell bases can become quite heavy. It is essential to assess whether you have the necessary lifting capacity to safely transport and install these base elements.

Differential Settlement - This phenomenon occurs when the prepared subbase settles at varying rates, potentially causing the culvert structure to shift over time. A continuous, cast-in-place culvert base can be engineered to accommodate these loads and maintain the alignment of the precast elements. To address the risk of differential settlement, precast bases may require specially designed joints or additional subbase preparation.

Cost - Generally, precast bases are less cost-effective than cast-in-place bases unless one or more of the aforementioned factors are relevant. It is important to recognize that precast bases may not be suitable for every project.

Need more information?

The expert team at Modcast can assist in assessing the suitability of precast bases for your next project, and provide budget costs. Reach out to learn more today.